Tai'an bearing grout is directly available in stock, sold by manufacturers, and the quality is stable

20 tons of Tai'an bearing grout were loaded and shipped

The bearing grout is in sufficient stock

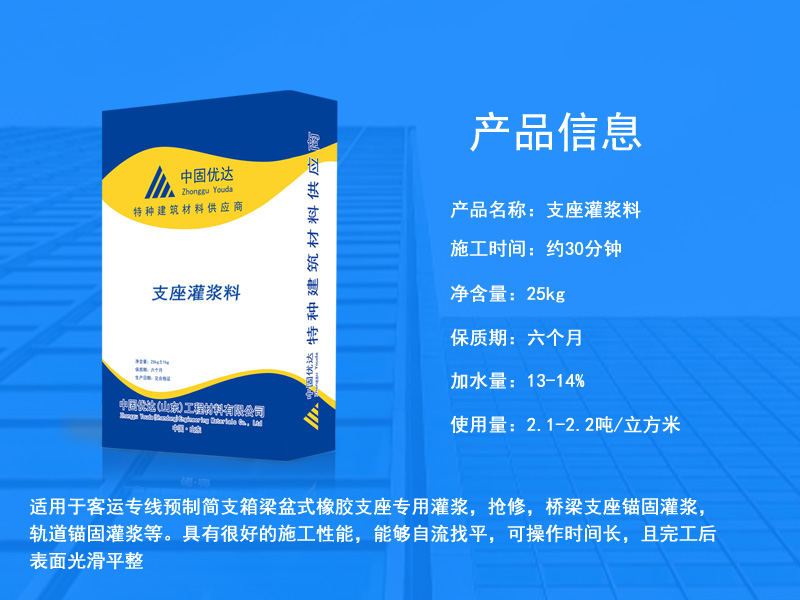

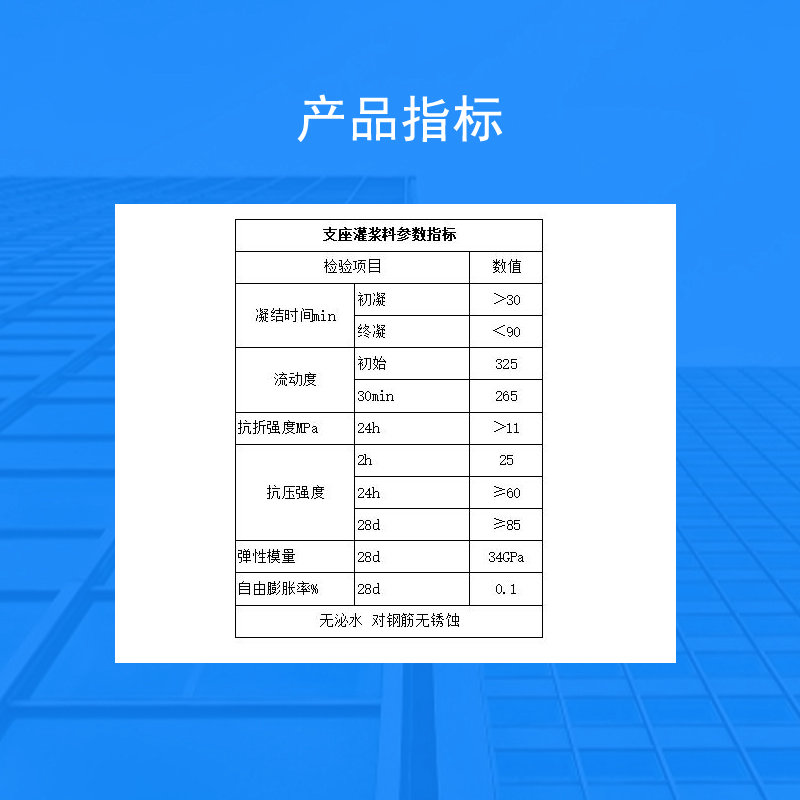

Bearing grout, also known as bearing mortar, wind power foundation grouting material bearing grout, M50 bridge bearing grout, bridge bearing grout, is a high-strength, high-density special grout, is a dry-mix cement-based grouting material made of cement as a binder, high-strength aggregate, expanded plasticizing components, polymer polymers and admixtures, the product is early and high-strength, 1 day compressive strength is greater than 40 megapascals, 28 days is greater than 85 megapascals, and the later strength will not shrink; In the case of the appropriate ratio of water and cement, it has great fluidity, can completely fill the grouting part, achieve self-leveling and self-compaction, so that the filling part has no shrinkage and micro-expansion, and the construction strength of the bearing grout still increases significantly in the sub-zero low temperature environment.

Jinan bearing grouting material has the characteristics of early strength and high strength, strong adhesion, impact resistance, fast curing speed, convenient construction, large flow self-compaction, stable performance, and prevention of steel bar corrosion.

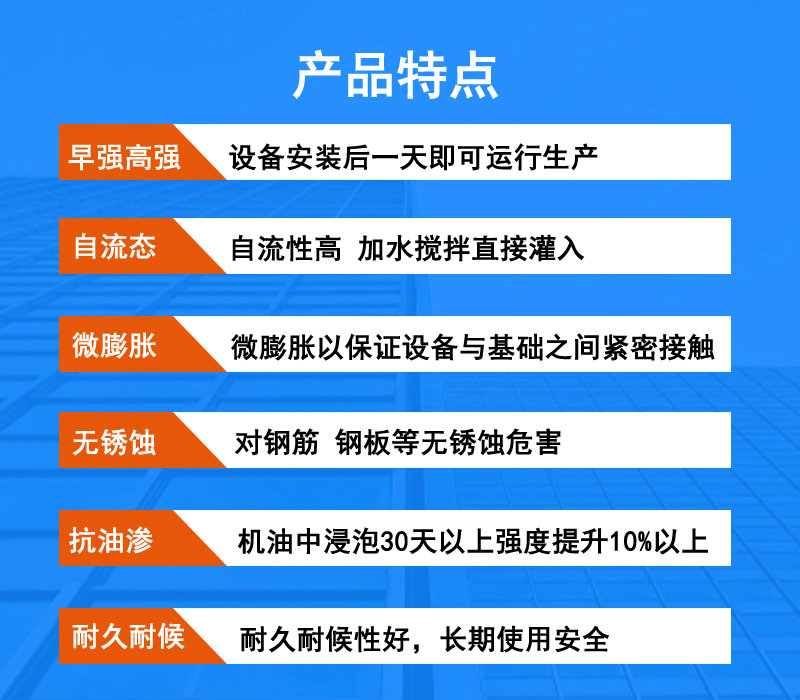

Product Features:

Early strength and high strength: 2~4 hours can reach more than 20MPa compressive strength High flexural strength, 28 days compressive strength more than 250MPa, high strength in the later stage and no shrinkage.

High fluidity: high fluidity can be achieved by adding water and stirring on site, and the voids can be filled without vibration and insertion.

Micro-expansion: The expansion value is short and the stability period ensures that the grouting material is in close contact with the grouting part and that there is no shrinkage.

Good workability: not only good flow but also long retention, with good cohesion, no stratification and no bleeding

Low temperature construction: the strength still increases greatly at low temperature, which effectively solves the problems of winter construction.

Good durability: 2 million fatigue tests, 50 freeze-thaw cycle tests, no significant change in strength; It has good performance in impermeability, frost resistance and corrosion resistance, and the steel bar is not corroded.

It does not contain chloride and has no corrosive effect on equipment and steel bars.

Easy to use: the finished product is dry mix mortar, which can be used after adding water according to the regulations on the construction site

The effective bearing area of the upper surface of the bearing grout is greater than 95%.

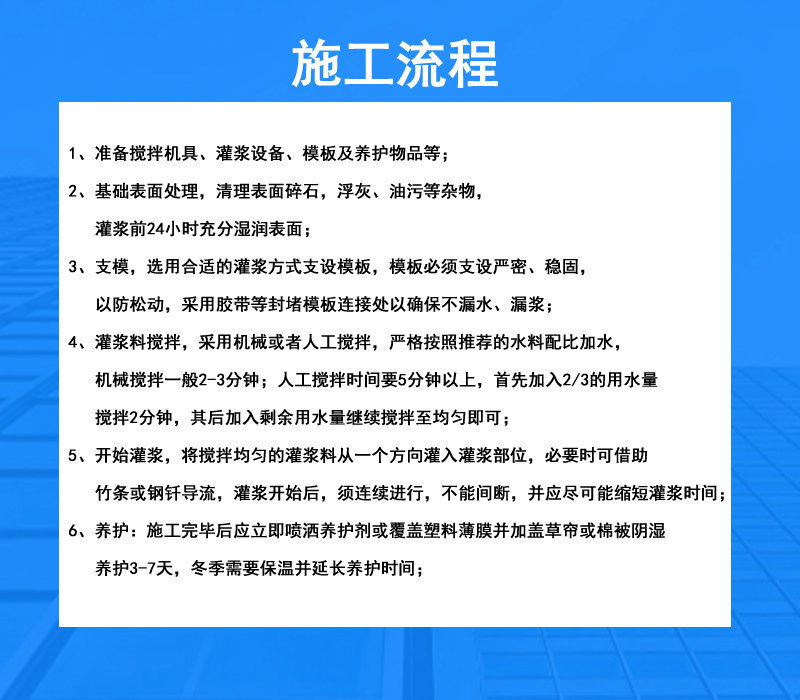

How to use:

1. Foundation treatment: the surface of the supporting cushion at the installation site of the chiseled bearing, clean up the debris in the reserved hole, install the grouting formwork, and take correct measures to prevent grouting leakage during gravity grouting. The base layer to be grouted should be cleaned of dust, oil and other dirt and other substances that are not conducive to bonding, and the layer should be moistened with clean water until saturated, but there should be no clear water left during construction.

2. Hoist the prefabricated box girder (with support), place the box girder on the temporary supporting dry jinjiang, and adjust the elevation of the fulcrum of the beam body by the jinjiang.

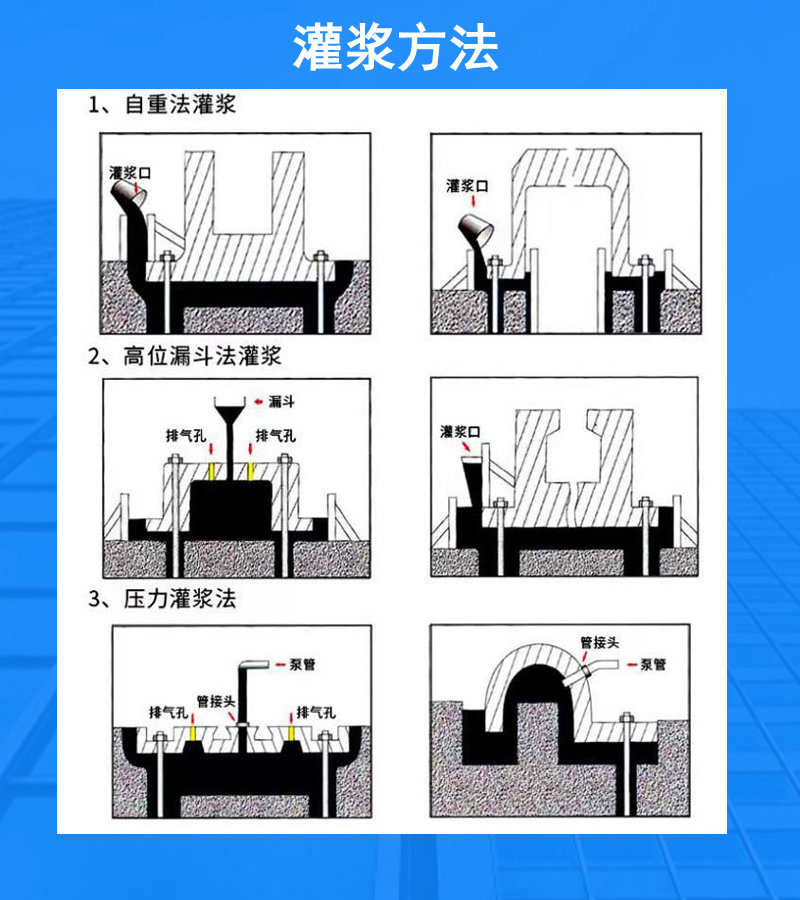

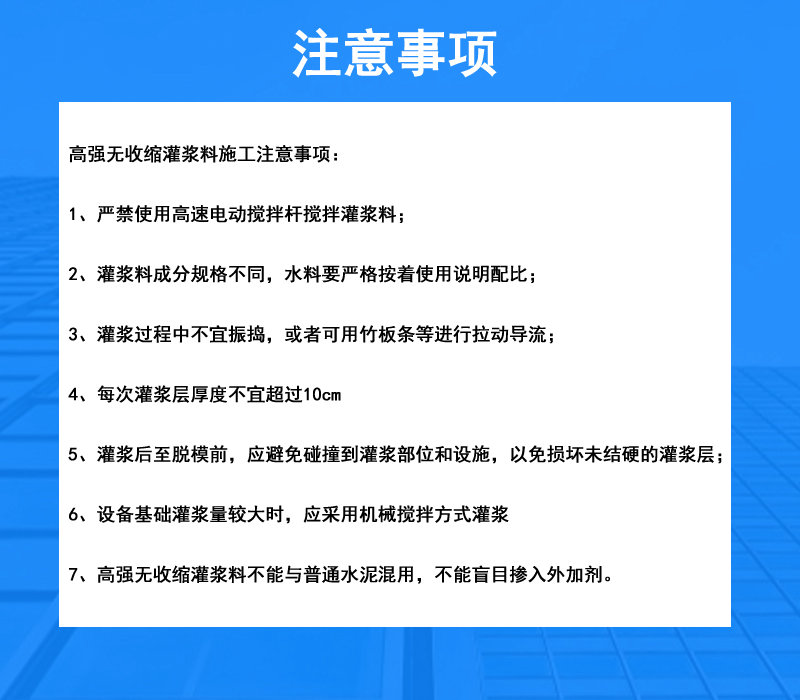

3. After the beam body is in place, a space of 20~30mm should be reserved between the base plate of the bearing and the supporting cushion stone of the pier and platform, which is convenient for pouring the grout material of the support with gravity grouting. 4. Use gravity grouting to submerge the gap at the bottom of the support and the hole of the wrong bolt. The grouting process should be filled from the middle of the bearing to the surrounding area until the filling is observed from the gap between the formwork and the base plate of the bearing. The required slurry volume should be preliminarily measured before grouting, and the actual amount of grouting should not have too much error with the calculated value to avoid slurry shortage in the middle. 5. The slurry is prepared according to powder: water = 1: (0.11~0.14) (weight ratio). Water should be added to the mixing bucket first, and then the weighed grout should be gradually added, and the electric mixer should be stirred while feeding until the powder is added, and then continue to stir for 2~3 minutes to make the reward material even

6. After the grouting material reaches the specified strength, remove the formwork, check whether there is any groutage, and make up for the grout.

7. Tighten the foot bolts of the lower support plate, remove the upper and lower bearings to connect the angle steel, remove the temporary jack, and install the support steel hoarding.

Link to this pagehttps://www.ygu5.com//product-detail/WeLyzA3N